Woven bags, a flexible packaging container made of chemical fibers such as polypropylene and polyethylene through drawing, weaving and sewing, are widely used in agriculture, industry, logistics and many other fields due to their low cost, high strength and corrosion resistance. In actual use, it is very important to choose a woven bag of the right size according to the type, weight and transportation requirements of the loaded items. Next, taking the common rice packaging as an example, the use size knowledge of woven bags is introduced in detail.

Woven bag sizes corresponding to different weights of rice

2.5kg rice woven bag

2.5kg rice usually uses a woven bag of 26cm*40cm size. This size of woven bag, with a horizontal width of 26cm and a vertical length of 40cm, can provide a relatively compact and suitable storage space for 2.5kg rice. On the one hand, it avoids the shaking of rice during transportation due to the bag being too large, and reduces the friction and damage between rice; on the other hand, the appropriate size is also convenient for handling and stacking, and the use of materials is more economical and reasonable, reducing the packaging cost.

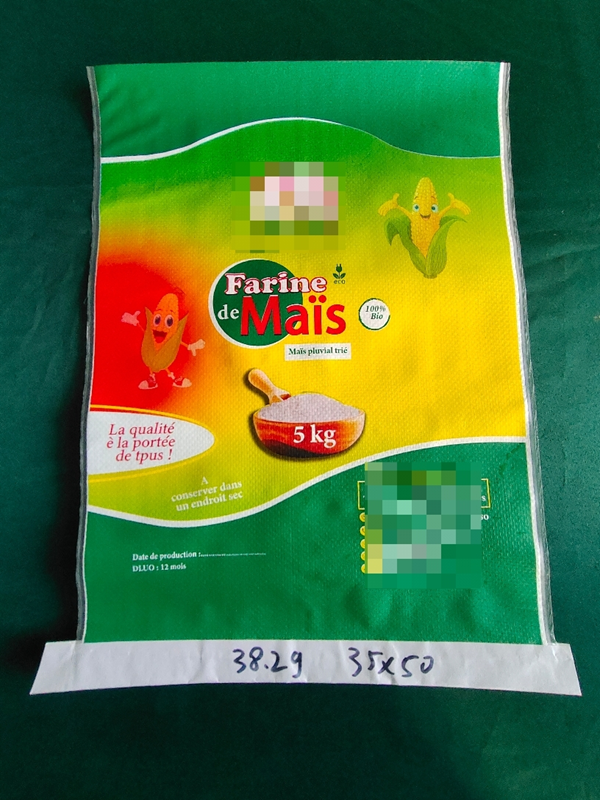

5kg rice woven bag

For 5kg rice, 30cm*50cm woven bags are a common choice. Compared with 2.5kg rice woven bags, it has a certain degree of increase in both horizontal and vertical directions. The horizontal width of 30cm and the vertical length of 50cm can better adapt to the volume and weight of 5kg rice, ensure the fullness and stability of the bag after the rice is loaded, and also facilitate users to carry and store.

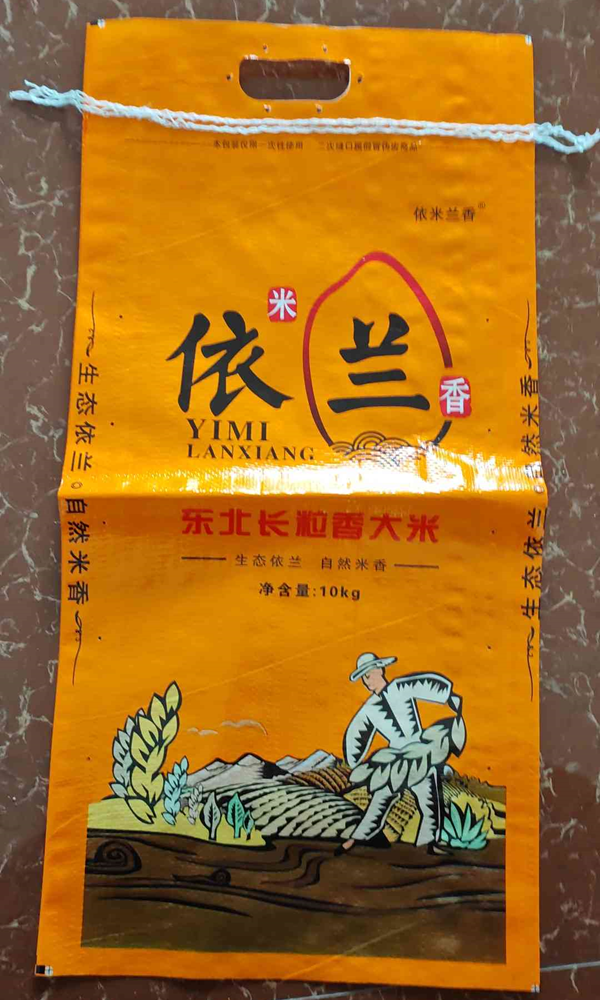

10kg rice woven bag

10kg rice generally uses 35cm*60cm woven bags. As the weight of rice increases, woven bags need to be larger in size to accommodate, and also have stronger carrying capacity. The width of 35cm and the length of 60cm can not only hold 10kg rice, but also disperse the pressure of rice on the bottom and sides of the bag to a certain extent, reducing the risk of bag damage. In addition, such a size is also easier to stack and carry during storage and transportation, improving space utilization.

15kg rice woven bag

The size of a 15kg rice bag is 40cm*60cm. At this weight level, the width of the woven bag is increased to 40cm, further increasing the lateral capacity of the bag. The length is kept at 60cm, mainly to ensure that the bag can hold 15kg of rice while maintaining the overall stability and practicality of the bag. After a woven bag of this size is filled with rice, it can better meet the needs of both transportation and storage.

25kg rice woven bag

25kg rice is usually packaged in a 45*78cm woven bag. Due to the heavy weight of rice, the size and strength of the woven bag are required to be higher. The width of 45cm and the length of 78cm provide sufficient space for 25kg rice, and can withstand the weight of rice, preventing the bag from breaking and leaking during transportation, loading and unloading. At the same time, the larger size also facilitates the filling and pouring of rice.

50kg rice woven bag

The size of a 50kg rice bag is 55*100cm. This is a large-size woven bag designed for heavy rice. The width of 55cm and the length of 100cm enable the woven bag to accommodate a large amount of rice, and the structure is reinforced to ensure that it can carry a weight of 50kg. This large-size woven bag is widely used in grain procurement and transportation, improving transportation efficiency and storage convenience.

Factors affecting the selection of woven bag size

In addition to rice, there are many factors to consider when choosing the size of woven bags for packaging other items. The first is the density of the item. Items with higher density, such as sand, gravel, cement, etc., have a smaller volume at the same weight, and a relatively smaller woven bag can be selected; while items with lower density, such as cotton, plush toys, etc., have a larger volume and require a larger woven bag. Secondly, the mode of transportation will also affect the selection of woven bag size. If it is long-distance transportation, considering the vehicle space and stacking stability, the size of the woven bag should not be too large; if it is short-distance transportation, the appropriate size can be selected according to the actual operational convenience. In addition, storage conditions are also critical. When warehouse space is limited, choosing a woven bag size that is easy to stack can improve space utilization.

Precautions for using woven bags

When using woven bags, in addition to choosing the right size, you also need to pay attention to some details. For example, when loading items, do not exceed the rated load of the woven bag to avoid damaging the bag; during transportation, avoid sharp objects scratching the woven bag; when storing woven bags, choose a dry and ventilated environment to prevent the woven bag from getting damp and aging, which will affect its service life.

Post time: Jun-26-2025